Form 337 Sheet Metal Repair Examaple

Vii thin sheet webs of beams.

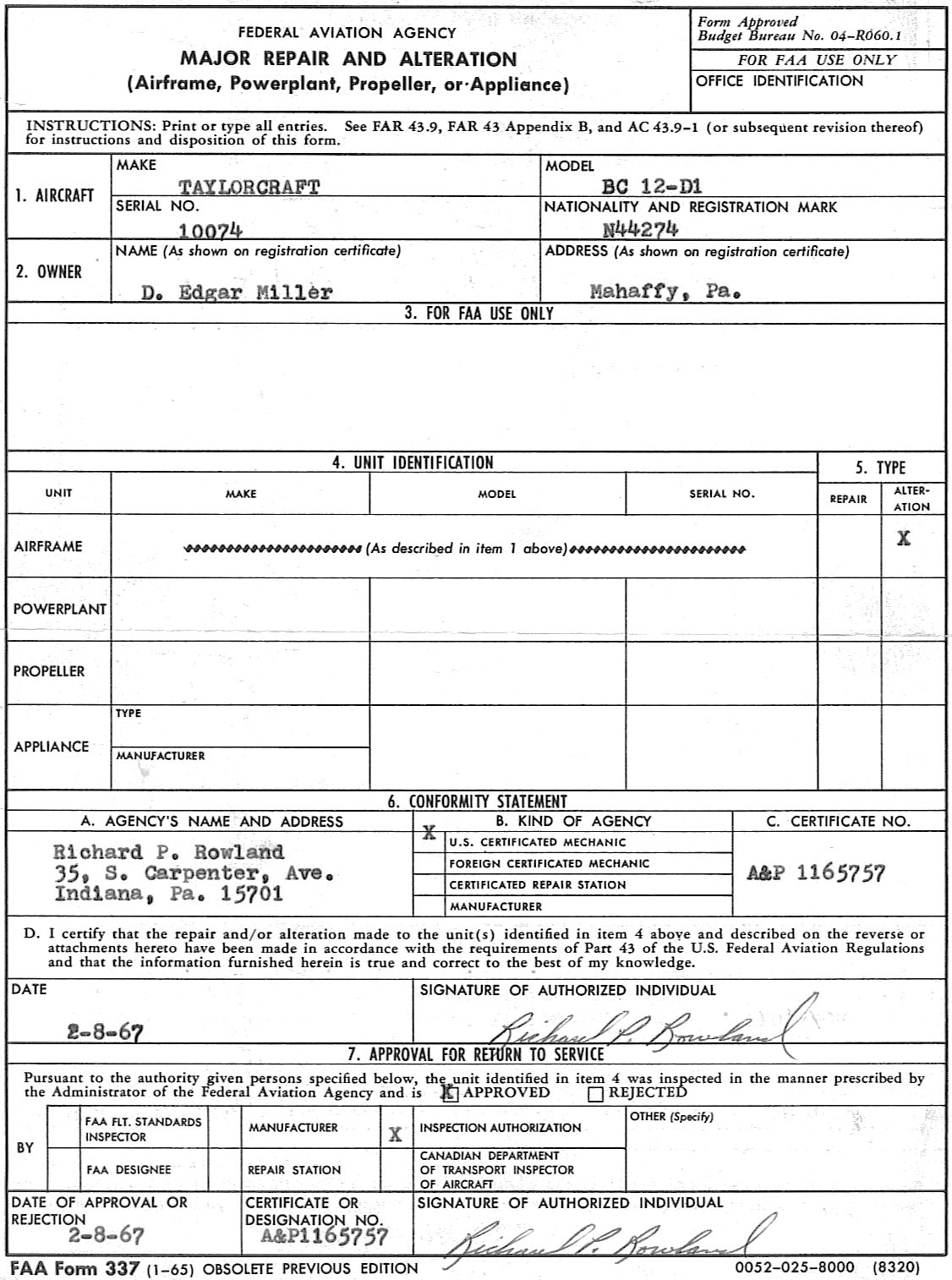

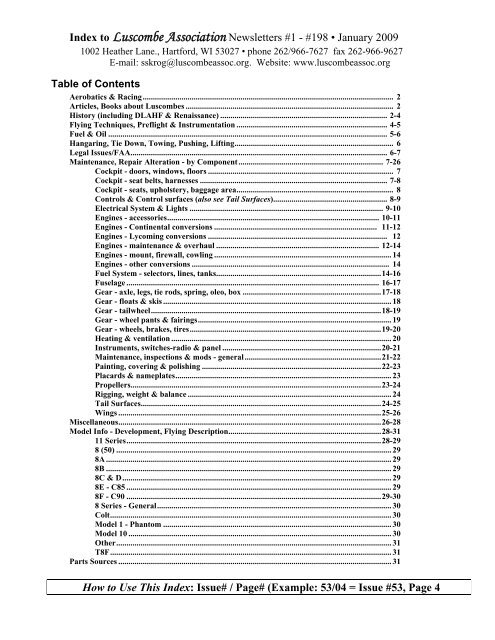

Form 337 sheet metal repair examaple. The following instructions apply to items 1 through 8 of. Example form 337 field approval author. What form must be completed when returning an aircraft to service following major structural repairs. Referenced form 337 and proposed changes to be made.

Faa 337 title major repair alteration airframe powerplant propeller or appliance edition date october 01 2006 orientation portrait unit of issue ea responsible office afs 350 comments. Willys cj3b jeep body fabrication side panels on the hammer form part 2 duration. Viii keel and chine members of boat hulls or floats. Da form 337 may 1959 created date.

Faa form 337 major repair alteration airframe powerplant prpeller appliance created date. Major repair and alteration of airframe powerplant propeller or appliance keywords. Noob with a. Reverse da form 337 may 1959 apd lc v2 00es.

Is not in excess of 50 000. Ix corrugated sheet compression members which act as flange material of wings or tail surfaces. X wing main ribs and compression members. A sheet metal repair to a pressurized structure may require the use of sealant.

Request for approval of disposal of buildings and improvements author. Sheet metal repair or patch easily. A fabricated part is considered consumed in a repair when it is installed into the next higher assembly component part or within a product by the fabricator while undergoing maintenance or an alteration. Xi wing or tail surface brace struts.

Faa form 337 major repair and alteration airframe powerplant propeller or appliance author. The estimated total sale value of the property is. Faa form 337 10 06 20 1r major repair and alteration 86 hsduwphqw ri 7udqvsruwdwlrq airframe powerplant propeller. The form is executed at least in duplicate and is used to record major repairs and major alterations made to an aircraft airframe powerplant propeller appliance or a component part thereof.