Fixing Plastic Sheeting To Wood

Use plastic sheeting that is equal to or greater than the height and length of the greenhouse walls so only one sheet.

Fixing plastic sheeting to wood. A good sanding pieces of wood helps prevent everything. They could rip your plastic sheet. These will stop the entry of rain wind and pests. We built an 8 x 9 ft gh last spring using 2x4s 2x3s and 2x2s.

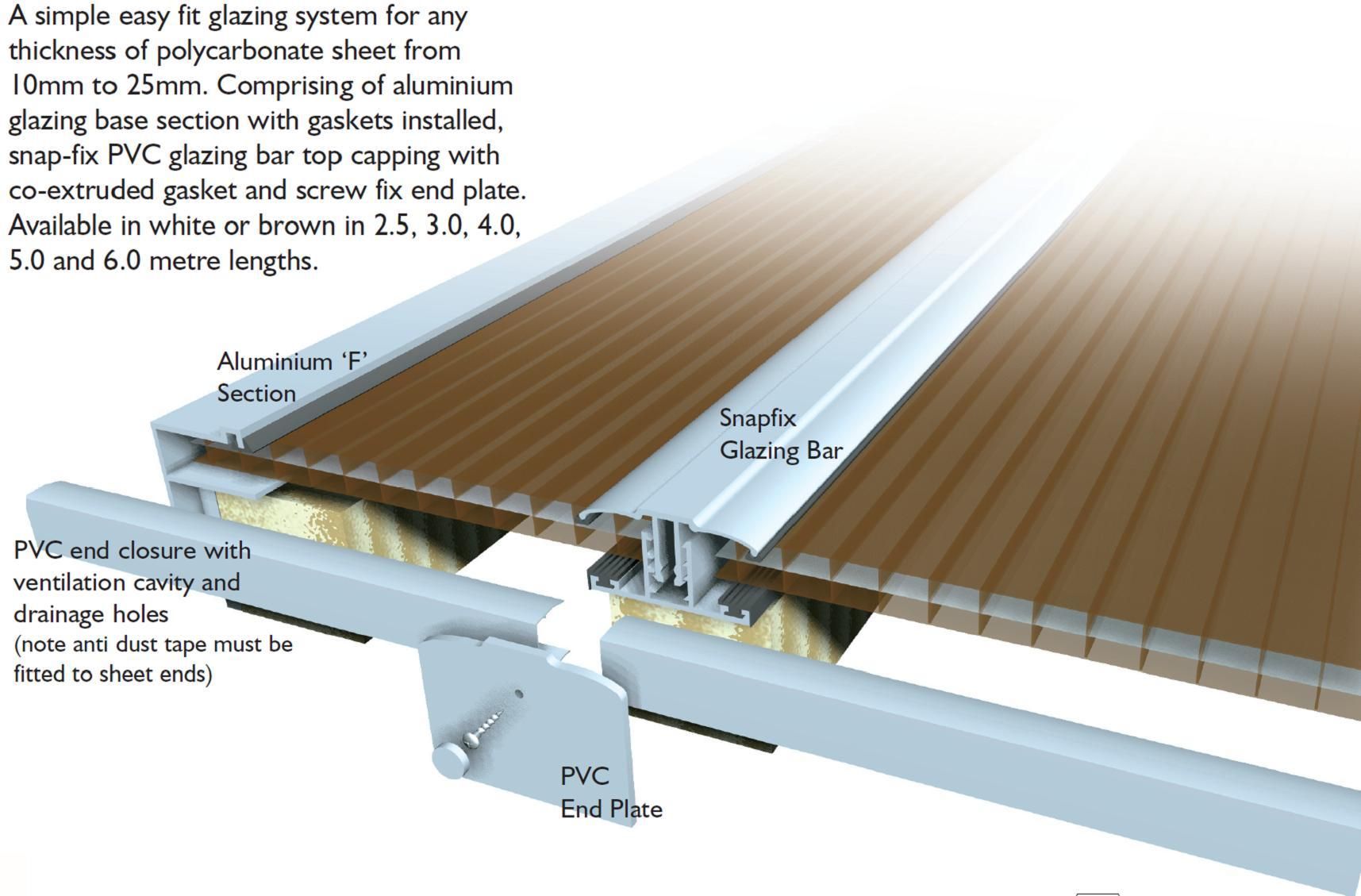

Polycarbonate sheets should be installed with the ribs running in the direction of the slope and it is recommended that at least one of the ribs is securely clamped in the glazing system. Nails should be no more than 30 cm apart do not use nails on their own to fix the sheet. Front end side walls and roof. 4 screw down the panels.

These strong yet lightweight roof sheets can be used on porches canopies rooflights cloche. Typically you can cover your greenhouse with 3 pieces. Sand the plastic surface lightly. Go over the broadest area of the plastic piece with a square of high grit sandpaper before you get gluing.

Avoid fastening plastic to a greenhouse on a windy day. Nail through the reinforcement bands if there are any. Do not use only one or two nails. Sanding the plastic will make it more porous and increase its overall surface area allowing it to bond to the wood more easily.

At the eaves purlin additional fixing is necessary to prevent wind uplift and downslope slippage due to repeated thermal movement. Epoxy is an especially useful adhesive for the bonding of smaller plastic pieces to wood glass metal and other materials used in crafting and other applications. Polyethylene is a good material for lean greenhouse or attached greenhouse too. Add a few inches to the dimensions of the plastic when cutting it to leave room for error and any inconsistencies in the.

Using plastic sheet polyethylene or poly to enclose a garden greenhouse is the most inexpensive way. Mix equal parts resin and hardener together in small quantities according to the manufacturer s instructions. I ll assume the plastic. Dries hard almost glassy.

Close or seal off the ends with a wood or plastic strip under the panel at each end. We get frequent wind around here and it only took about 3 4 months before the plastic started tearing primarily on the south side. Do not split the wood with the nails. Used pc panels for roof to prevent snow collapse and 6 mil plastic for sides.

Fixing plastic sheeting to wood nail the plastic sheeting around an edge for strength. Survives extreme temperature fluctuations.