Fix No Flashing At Wall To Roof Connection

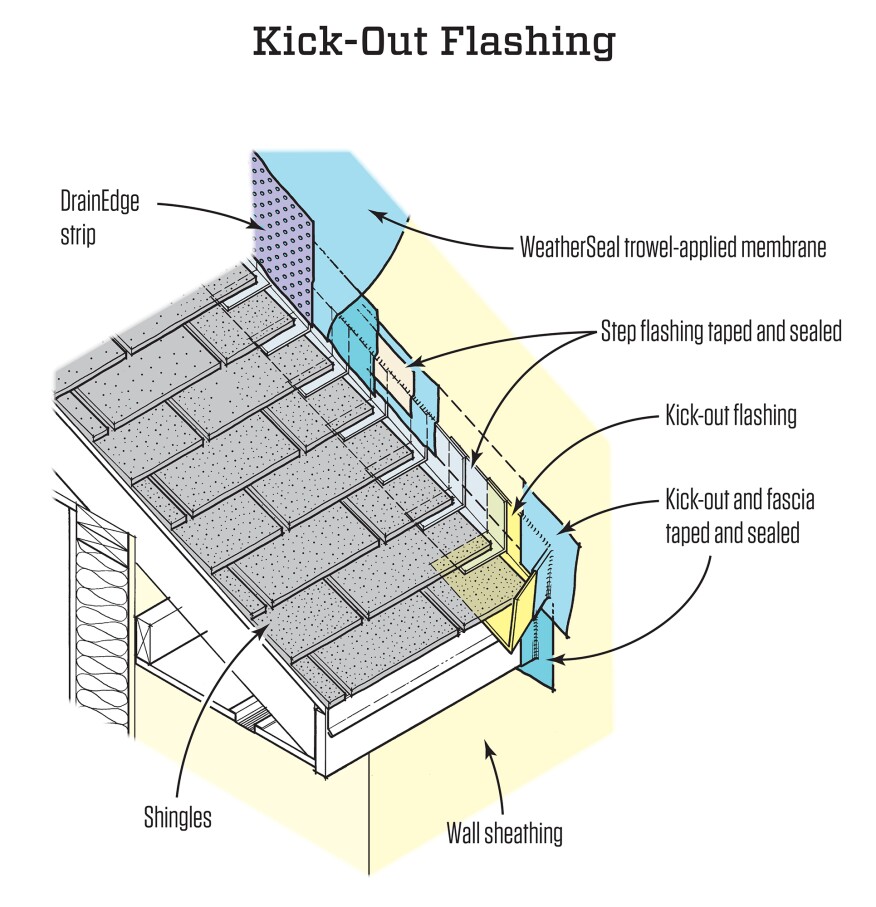

1 run membrane down the side of the block and onto the roof underlayment.

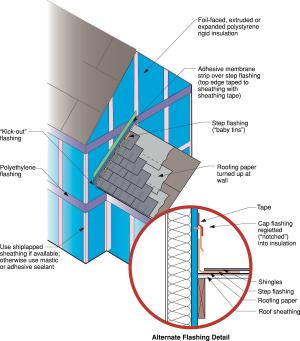

Fix no flashing at wall to roof connection. Flashing materials choices installation details specifications. Bend the corner flashing tightly around the corner. 2 fold a vertical strip into the inside corner extending it above the top of the block so that the next layer of flashing will cover it shingle style. And 3 cap the block with membrane overlapping the first two pieces and bridging the gap between the block and the wall sheathing.

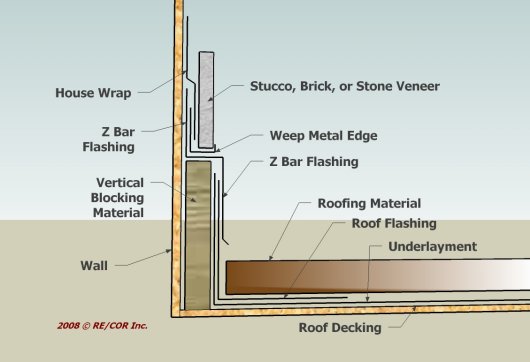

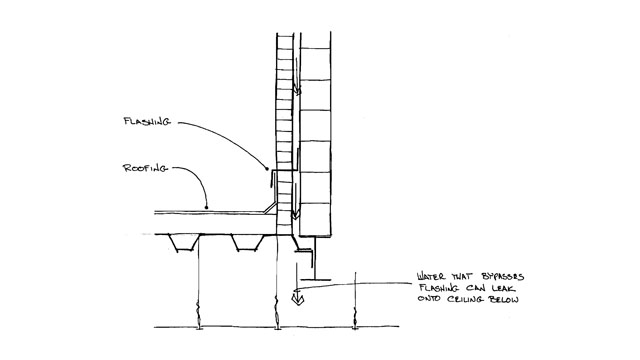

Proper roof wall flashing example. Roofing cement can dry out and crumble away exposing joints to water. To install the roof wall flashing above the builder bent the top edge of the flashing into a 90 degree lip about 2 cm in width. Look for loose nails and any damage to the seals at the edges of the flashing.

And exposed misplaced roofing repair nails should be pulled and the holes patched. Roof shingle over step flashing. Above the roof sheathing. Despite the numerous.

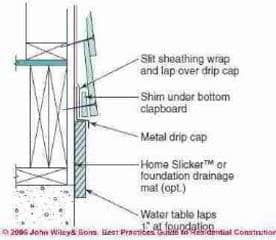

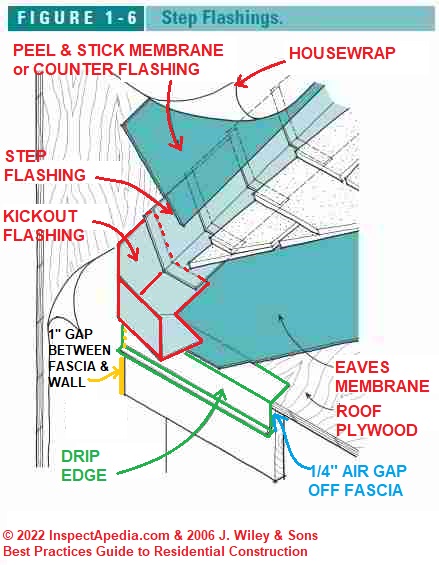

Use a metal break tool to bend the flashing according to the angle of the roof joint. This aritcle describes the cause repair and prevention of leaks rot damage at a wood framed wall that was not properly flashed and sealed at the wall bottom. I use a wide piece of flexible flashing tape to protect the area between the subfascia and the wall. Step flashing on roof peak.

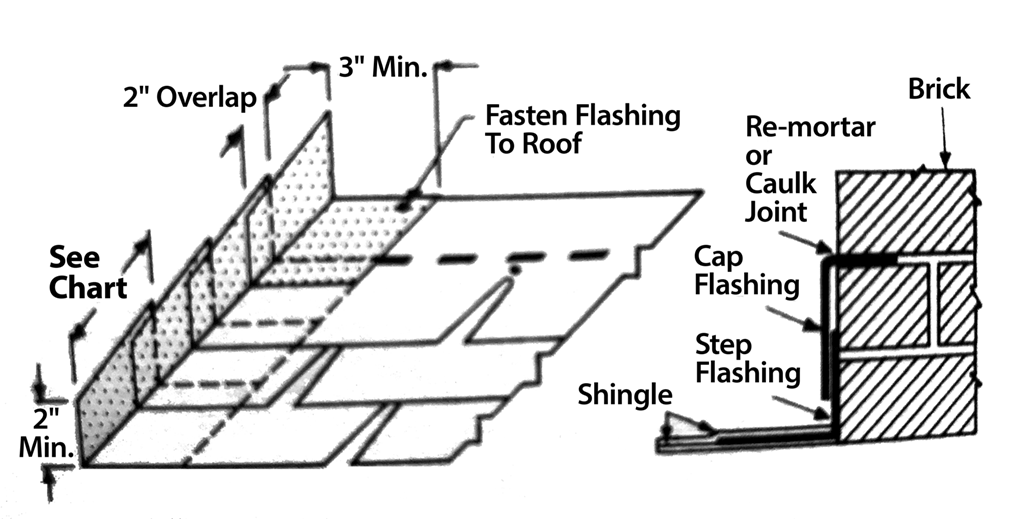

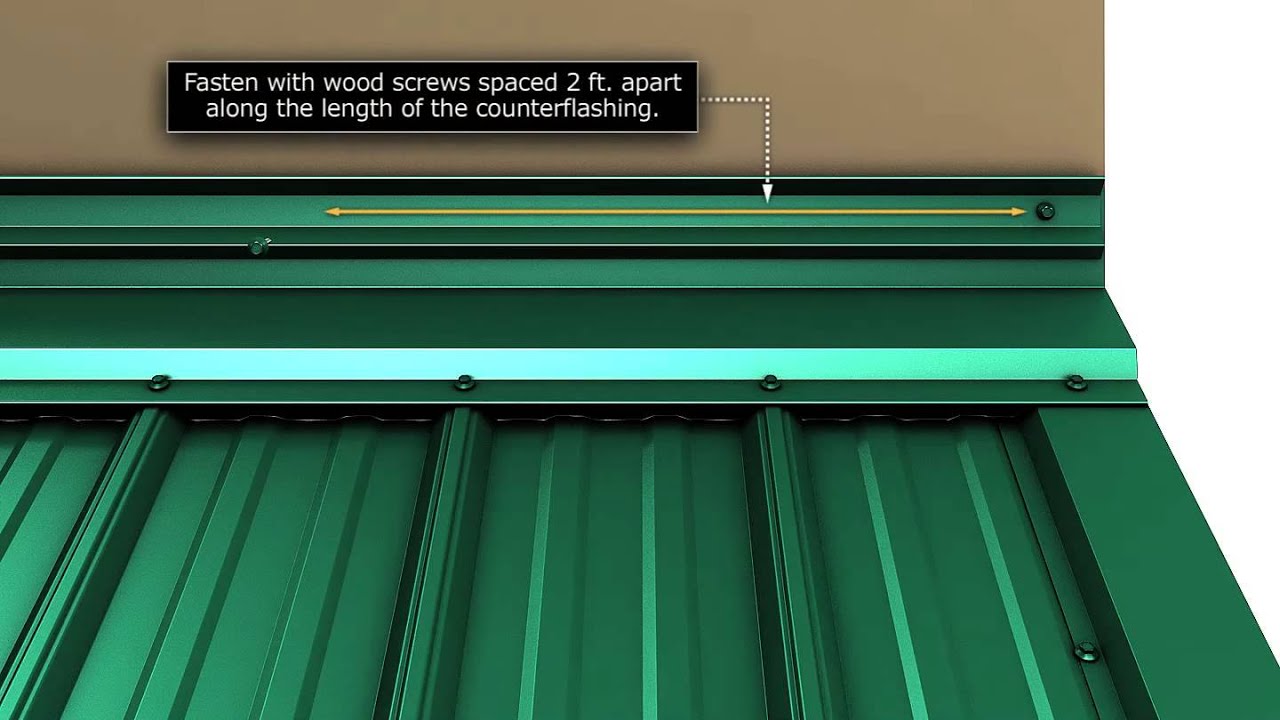

You ll fix this leaky roof problem with flashing. That lip is then set into a reglet or groove in this case cut into the mortar joint of the brick wall above. Fasten loose nails and cover exposed nail heads with roofing cement. If you do not wish to form your own corner flashing you can buy pre bent pieces and cut them to size or use a piece of corrugated aluminum which is easier to bend.

Roofs are typically covered in asphalt shingles but sheet metal and natural stone pieces are also used as are clay and concrete roof tiles. Once the flexible flashing is set i apply a piece of housewrap along the wall where the fascia meets it. Flashing is generally 8 inches wide with 4 inches going on the wall of the house and 4 inches going on the top of the roof shingles. Flexible flashing tape seals the eave to the wall.

Wall or siding connection to foundation top porch floors slabs. I cut the tape so that it laps onto the housewrap above and 3 in. Always check the roof flashing and the condition of the shingles whenever you clean your gutters. Cut the flashing with tin snips if you need to cut it.

Check out our recommended tools right here. Small holes are simple to fix but the fix isn t to inject caulk in the hole. You might find holes left over from a satellite dish or antenna mounting brackets or just about anything. Building wall or siding flashing details at horizontal surfaces.