Edit Gap On Sheet Metal Flange

Products and versions covered inventor 2015 inventor 2016 inventor 2017 inventor 2018 inventor professional 2015 inventor professional 2016 inventor professional 2017 inventor professional 2018.

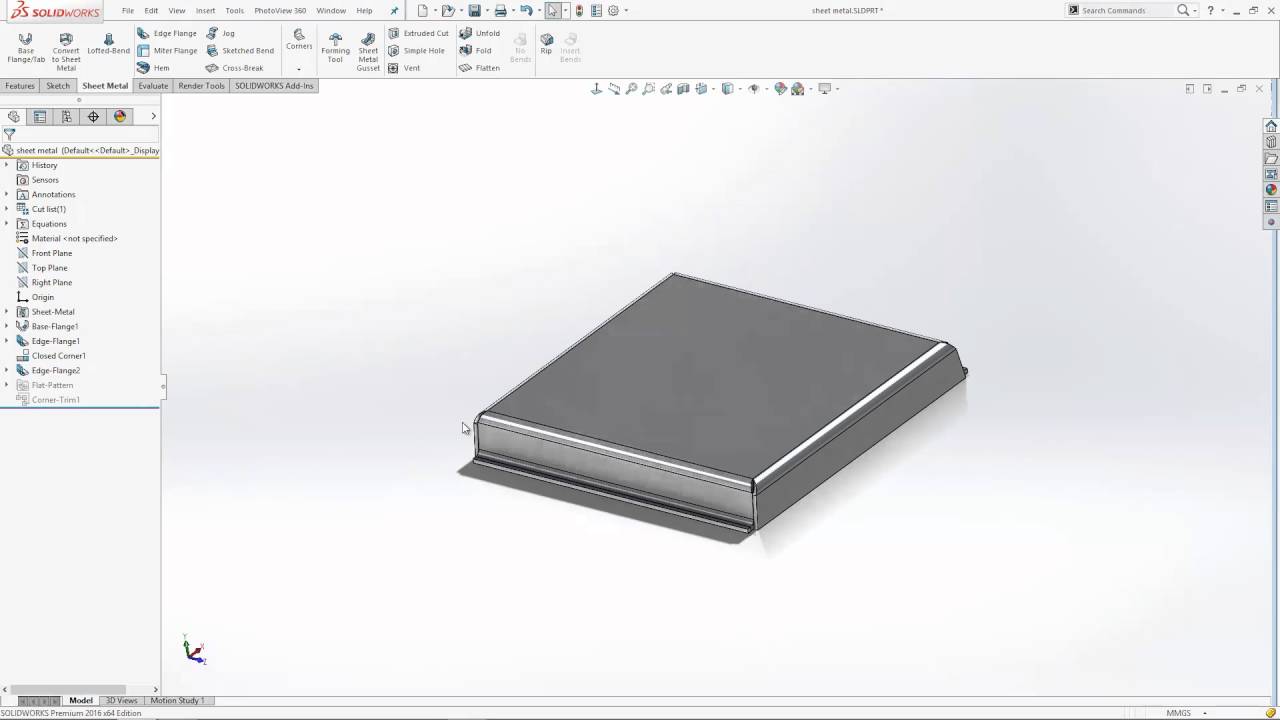

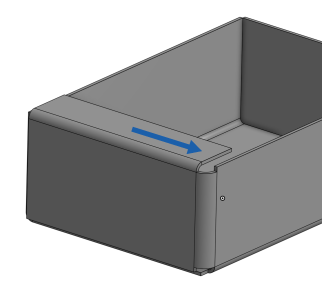

Edit gap on sheet metal flange. So i created the flanges via the face command then a clearance notch then using the fold command. Edit the sketch of the profile. There is note of it in the help documentation as to better support multiple instances within a feature the embedded sketch functionality has been removed. To add a flange feature you select one or more edges and specify the size and position of the material added.

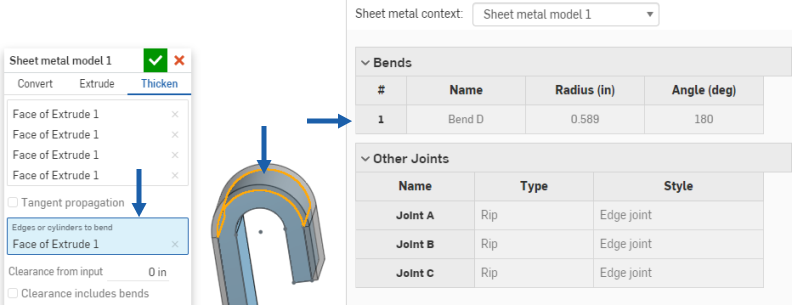

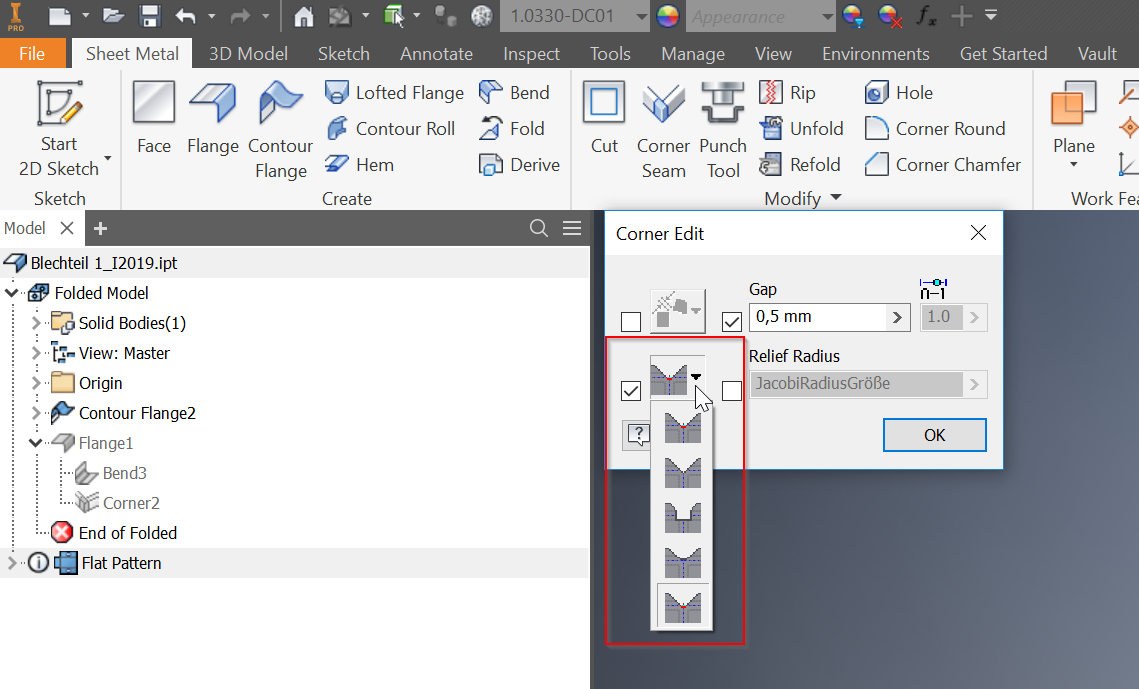

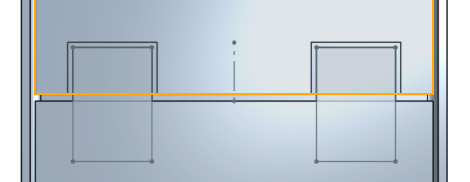

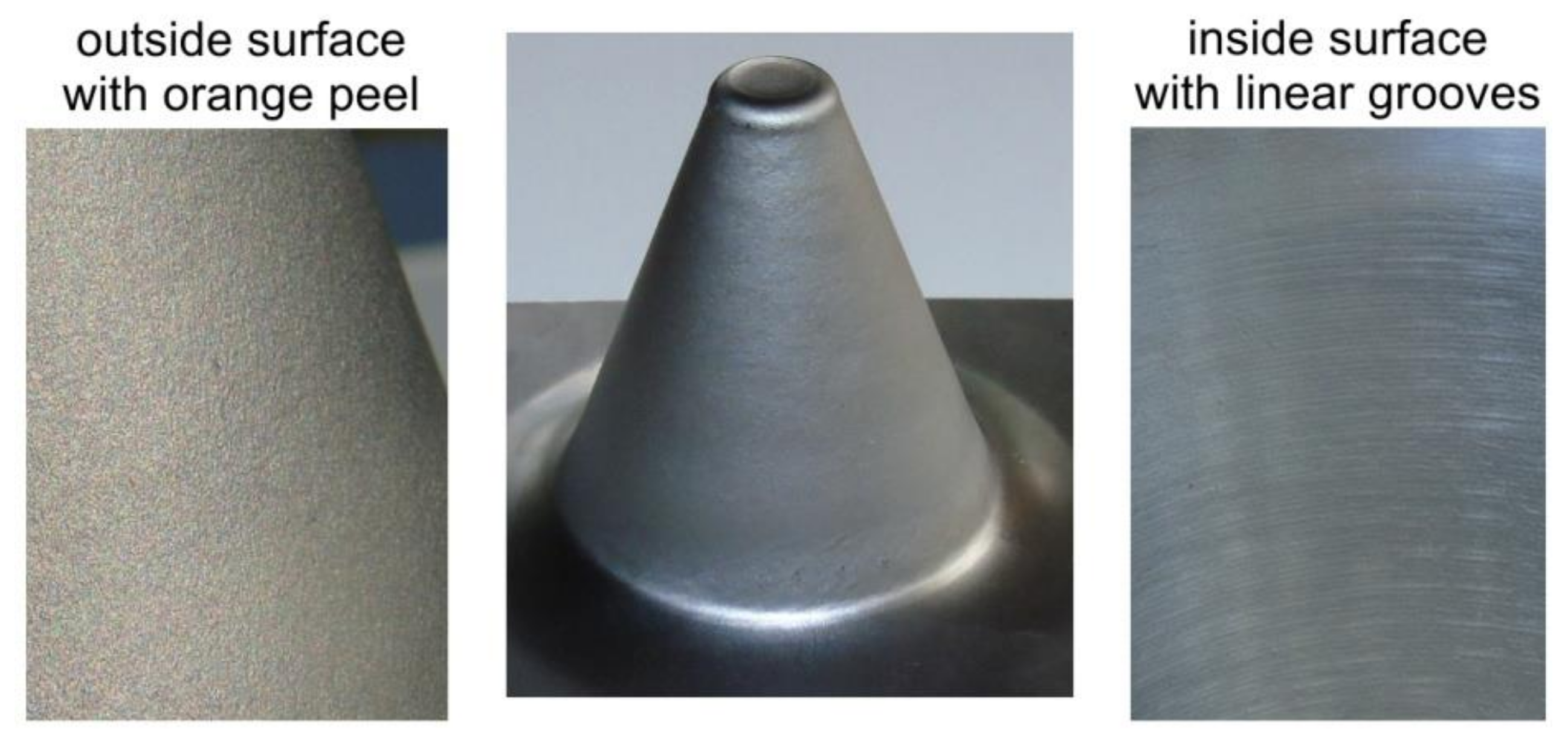

Corners that generate during the creation of flange and contour flange features display the default corner relief shape when the model is flat. Previous editions covered economic order quantity in batch production and the accuracy of things made from rolled sheet stock. I was not able to create the triple flange using the sheet metal tools directly. The formed sheet metal bend with the relief cut at the end of the flange is one preferred approach.

You could also make a helical surface transition from the flat section to the flange end face with the appropriate bend mold line allowance in the flat pattern. Next month concludes with the pros and cons of hems jogs and forming tools. Choose the back edge of the base flangeas the edge on which you wish to create the edge flange. The image showing a formed transition with sharp corners is not practical.

You can override the default sheet metal. How can i decrease the gap between the ends of the flanges. The default radius of1mm is used. A flange feature consists of a face and bend connected to an existing face along a straight edge.

Columnist gerald davis continues a discussion of 3 d cad and precision sheet metal manufacturing in part iii of a four part series focusing on design guidelines for sheet metal. Set a value when use default radius and use gauge table are cleared. Drag the edge upwards and left click to indicate direction and an initial value for length. It is designed behavior as a part of flange enhancements in nx12.

Cannot edit the corner gap in a sheet metal flange part file. Use gauge table only available if a sheet metal gauge table has been selected for the part select or clear. Then find out how to flatten parts and add holes cuts and corners that are manufacturing ready and use the convert to sheet metal command to convert imported geometry into native sheet metal parts. Is this the only way to create adjoining flanges that are not oriented 90 degrees apart.